Reduce Costs with an Air Audit

How do you eliminate compressed air energy waste? Call John Henry Foster, St. Louis’ ROI Group and order a Compressed Air System Audit.

Compressed air generally accounts for over 40% of power expenses in manufacturing facilities. Fine – except up to HALF of that air is lost to waste. Leaks, inefficient use, and artificial demand lead the list of waste, but there are other sources as well.

A JHF Systems Audit will help you find and eliminate much of that wasted air. Our compressed air experts will work with you to align your needs with our capabilities.

JHF Air System Assessments set a new standard in compressed air audits.

Why John Henry Foster?

You have options when it comes to assessing your compressed air usage and wastage – so why hire JHF?

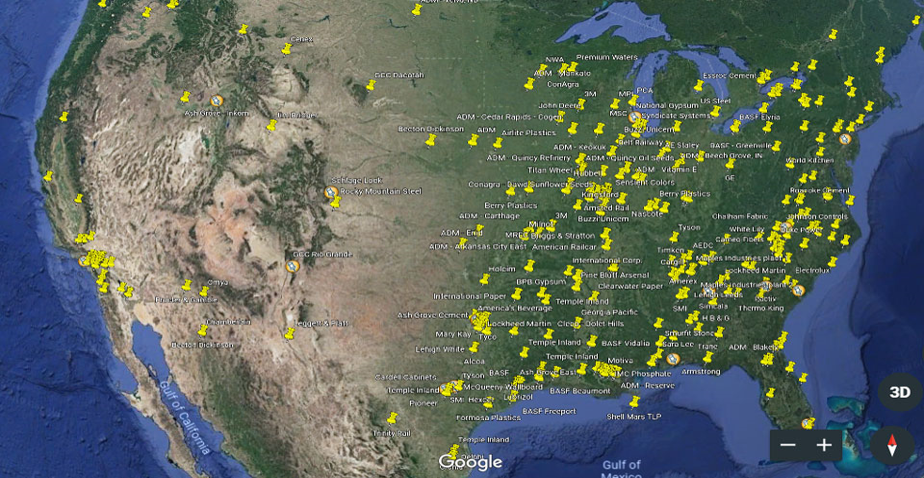

JHF has over 100 years’ experience working with compressed air in St. Louis, MO:

Industries we've audited include:

Ameren

JHF is an Ameren-registered Service Provider and Ally. Through JHF you may qualify for cash incentives, including:

Meet Your Partners in Air Efficiency

Mark Ames

Bryan Crane

Matt Miller

Nathan Black

Kevin Silate

- Chemical, petroleum, and corn refining

- Coal and natural gas power plants

- Plastics- thermoforming, injection molding, PET

- Cement

- Steel

- Pharmaceutical

- Aviation

- Paper

- Food processing

- Various other manufacturers

- Reducing energy

- Improving reliability

- Reducing the risk of a production interruption

- Improving compressed air quality (pressure dewpoint and pressure stability)

- Increasing supply repeatability and resiliency

- 15 years at Ingersoll Rand

- Service technician

- System auditor

- General line sales

- Regional manager for the Centac group

- Product Manager for the Compressed Air and Tool Group

- Return on Investment Business Manager

- System controls

- System Design

- Enhancements and ROI projects

- Sustainability Programs

- 4 years in Aviation Electronics in the United States Marine Corps

- 10 years in Industrial Automation and Compressed Air Repair

- 3 years in Automation Implementation and Troubleshooting at John Henry Foster Co.

- Degree in Automation and Robotics

- Automated Air System Controls- Implementation and Tuning

- Electrical and Mechanical Troubleshooting

- Compressor Performance and Capability Testing

- System Validation

- Air Leak Assessments

- 9 years at Ingersoll Rand as Service Coordinator and Service Manager

- Aftermarket/Unit Service and Sales

- Air System Auditor/Project Manager

- System Audits

- System Design

- Sustainability Partner

- Compressed Air Behavioralist

Mark Ames

- Chemical, petroleum, and corn refining

- Coal and natural gas power plants

- Plastics- thermoforming, injection molding, PET

- Cement

- Steel

- Pharmaceutical

- Aviation

- Paper

- Food processing

- Various other manufacturers

- Reducing energy

- Improving reliability

- Reducing the risk of a production interruption

- Improving compressed air quality (pressure dewpoint and pressure stability)

- Increasing supply repeatability and resiliency

Bryan Crane

Bryan Crane has 20 years of experience at John Henry Foster and Ingersoll Rand Company in the compressed air industry

- 15 years at Ingersoll Rand

- Service technician

- System auditor

- General line sales

- Regional manager for the Centac group

5 years at John Henry Foster

- Product Manager for the Compressed Air and Tool Group

- Return on Investment Business Manager

Areas of Expertise:

- System controls

- System Design

- Enhancements and ROI projects

- Sustainability Programs

Matt Miller

Matt Miller has 17 years of experience involving Electrical Automation and Compressed Air

- 4 years in Aviation Electronics in the United States Marine Corps

- 10 years in Industrial Automation and Compressed Air Repair

- 3 years in Automation Implementation and Troubleshooting at John Henry Foster Co.

- Degree in Automation and Robotics

Specializing in:

- Automated Air System Controls- Implementation and Tuning

- Electrical and Mechanical Troubleshooting

- Compressor Performance and Capability Testing

- System Validation

- Air Leak Assessments

Nathan Black

Nathan Black has 12 years of experience at John Henry Foster and Ingersoll Rand Company in the compressed air industry

- 9 years at Ingersoll Rand as Service Coordinator and Service Manager

3 years at John Henry Foster

- Aftermarket/Unit Service and Sales

- Air System Auditor/Project Manager

Areas of expertise:

- System Audits

- System Design

- Sustainability Partner

- Compressed Air Behavioralist

Contact JHF's ROI Group

Let's find a way to put the JHF Difference to work for you!