At John Henry Foster, we know compressed air. But no one knows your business and your objectives like you do. That’s why we use a collaborative, customer-first approach to guarantee the results you expect.

Understanding your system – the challenges you face with your compressed air and your desired outcome – helps us achieve and sustain specific, measurable system performance.

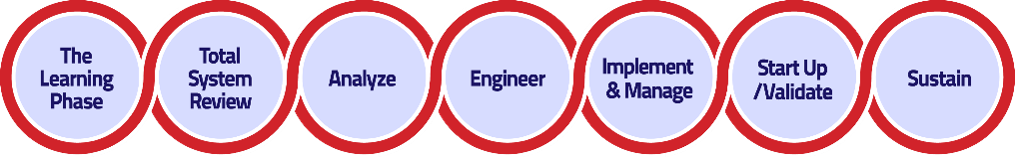

Process Makes Perfect

We’ll get to know your system & requirements so we can align our capabilities with your ultimate objectives.

- Measure supply flow with a series of tests with amp clamps and pressure transducers to ensure efficient operation

- Determine pressure deltas both on clean-up equipment and in remote areas of the facility to determine if changes are necessary.

- Correlate and compare supply flow to potential flow

- Explore potential modes of control on the compressors to increase efficiency

- Review alternatives for additional/replacement equipment (dry compressors, etc) or components for maximum productivity.

- Develop a performance specification

- Create drawings and scope of work for the project

- Determine any possible technical issue

- Manage delivery schedule

- Manage contractor schedule

- Communication cadence between all interested parties

- System set-up

- Train facility personnel on proper use

- Provide Validation report outlining savings

- Maintain performance

- Provide Technical Assistance

- Regular follow-ups

Contact JHF's ROI Group

Let's find a way to put the JHF Difference to work for you!