Compressed Air Theory vs Reality

Supporting production in today’s ever-changing world is challenging for large or small operations. Compressed air adds another layer to that challenge due to the complexity of most air systems.

Theory… especially that of efficient compressed air performance, can make you feel better – the salesperson and their marketing material assures you clean, dry air in the header, at nice steady 100psig, and production will always be happy. Reality says, “not so fast – you live in reality… and reality tends to be more challenging.”

At John Henry Foster, St. Louis, understand that theory doesn’t produce sustainable performance and results. That’s why, we live ONLY in reality.

Realities of compressed air efficiency

So how do you most effectively deal with reality?

Here are some questions to ask your current or potential vendors:

Your vendor’s goal should align with your goal - getting the most data from every component and best control while maximizing electrical savings. All that while satisfying production – who is absolutely, still king.

Process Makes Perfect

John Henry Foster’s Compressed Air and Controls experts offer you the peace-of-mind that comes with unmatched compressed air experience, a results-guaranteed process, and a dedication to sustaining energy savings.

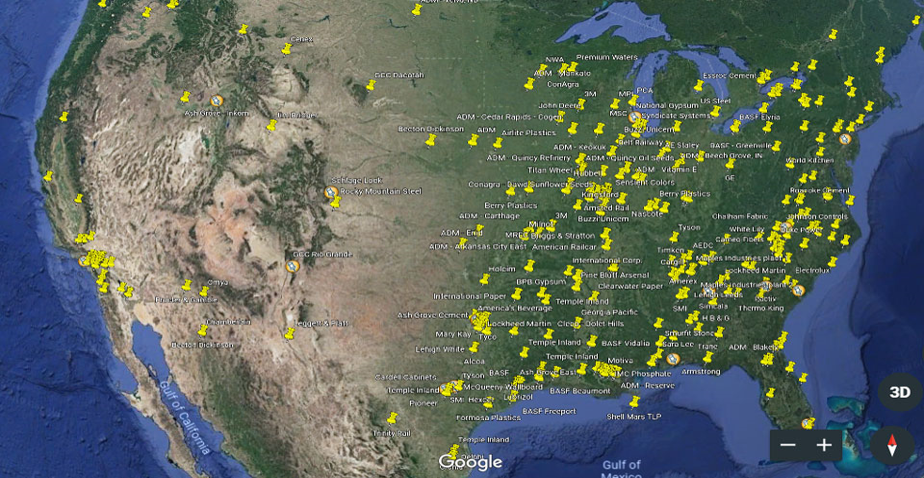

With an extensive resume of air assessments and project implementations-conducted in all environments-across the US and internationally, our team will help you identify efficiency opportunities, in any application- regardless of system complexity.

Over 100 Years of experience involving compressed air

Specialize in system analysis, design, and performance

Provide solutions to meet customer goals that include eliminating energy waste and improving productivity

Ameren Registered Service Provider and Ally

Receive hassle-free energy efficiency incentives offered by Ameren

Contact JHF's ROI Group

Let's find a way to put the JHF Difference to work for you!