Corporate Energy Project Management

Having an energy management strategy is imperative in today’s world…especially, in the corporate environment. Energy- including compressed air energy- is among the biggest cost areas for companies but often, it is the only cost that is not monitored and managed carefully.

John Henry Foster can help.

Our team is focused on helping our corporate clients achieve compressed air energy efficiency. With over a century of experience in large, multi-faceted organizations, we support our corporate clients develop results-guaranteed strategies to eliminate waste. With John Henry Foster, you now have a partner who will continually monitor and correct compressed air applications.

Benefits of Multi-Location Energy Management Projects

Multi-facility organizations benefit from cost savings as we implement and commission the first one or two locations. As results are realized and risks are minimized, the strategy becomes more viable and easily implemented throughout other facilities.

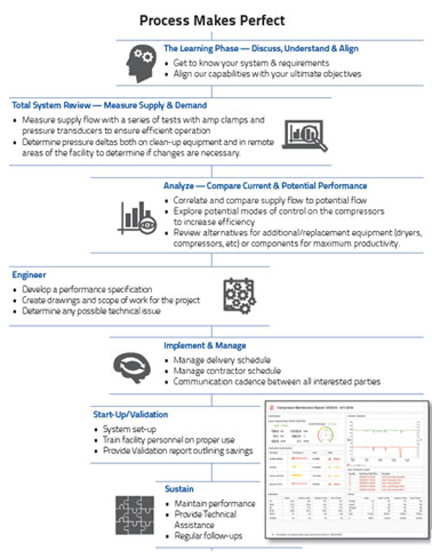

A Results-Guaranteed Process

By following our refined and guaranteed process, we will develop and implement an organization-specific strategy to help you eliminate compressed air energy waste, allowing you to focus important resources, elsewhere.

- Establish an actual, real-time baseline of performance and energy consumption of your compressed air system (calculating the predicted vs actual amount of energy being consumed)

- Monitor and analyze energy usage and performance of your compressed air equipment (analyze equipment individually and as a system)

- Ensure your equipment is performing as promised and as needed

- Discover opportunities for energy efficiency improvements

- Present findings and suggestions to the appropriate team

- Assist with the implementations of any necessary equipment/controls

- Train your employees to monitor and assess ongoing energy consumption

- Regular communication to ensure sustainability of energy efficiency efforts/projects

- Ensure you follow the appropriate steps to apply for and receive energy rebates and incentives